How a Novice to Start a Business of Cellphone Repair

Difficulty

★☆☆ Low

Step

4

Required Time

20 minutes

Excerpt

With the development of mobile phones, the demands for mobile phone repair is also higher and higher. Especially for the area of the mobile phone’s screen repair, so today we would tell you about if a novice wants to engage in cellphone repair industry, what he/she should have?

Accessories

separator wire, manual separator machine, freezing separator machine, glue remover, cleansers (8333 & 9666), push wheel, all-mighty laminating mold, new front glasses, special-made curved mold, RMB-2 laminatingn machine

With the development of mobile phones, the demands for mobile phone repair is also higher and higher. Especially for the area of the mobile phone’s screen repair, so today we would tell you about if a novice wants to engage in cellphone repair industry, what he/she should have?

In general, we need three things. The first one is tools. The second one is consumables. The third one is repair skills.

When we go through each step, we would introduce it to you.

The first step is separating.

For a broken cellphone screen, the first step we have to do is separate the front glass so we need a steel wire and some part of manual separator machine, that is the heating platform.

In addition, if we need to separate some edge screens, we may also need to use a freezing separator machine which is specialized used for edge screens and it can improve your working efficiency. It is like what you see in the picture, that is our frozen machine.

The second step is cleaning.

For the step of cleaning up the residual glue which is remaining on the front glass, we need to use a glue remover and some cleanser. These two cleansers (8333 & 9666) can help us to remove and clean up the residual glue on the front glass.

The third step is OCA laminating.

After cleaning the residual glue, we should stick a piece of the OCA to a new glass or the LCD.

That is the push wheel. This is our common used tool. It can help us to stick a piece of the OCA to the LCD or to the glass easily.

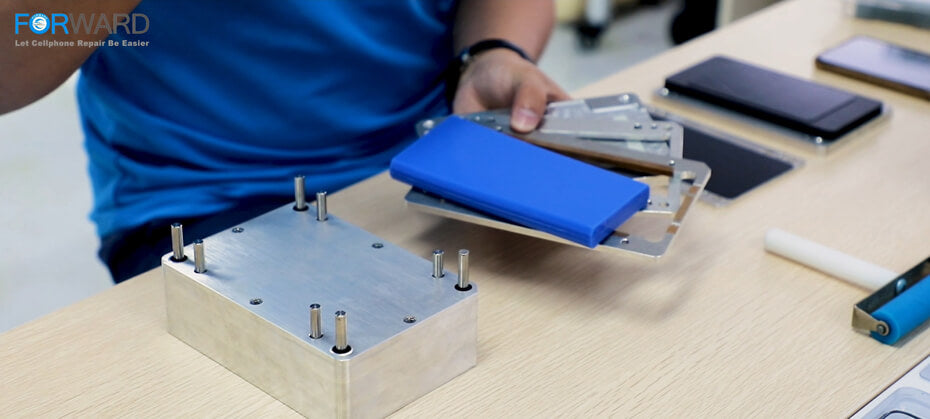

Yet for a novice, it would often have a deviation when he uses this tool. To avoid this problem, we specially make an all-mighty laminating mold to bond OCA for the beginners. The beginners can use it to align the position easier and more accurate.

The last step is LCD laminating.

After we finish laminating the OCA, the next part we have to do is bond a new glass to the LCD.

We should use some consumables in this process at this time.

These consumables are the front glasses what we are seeing in below picture. That is what we call the external screen.

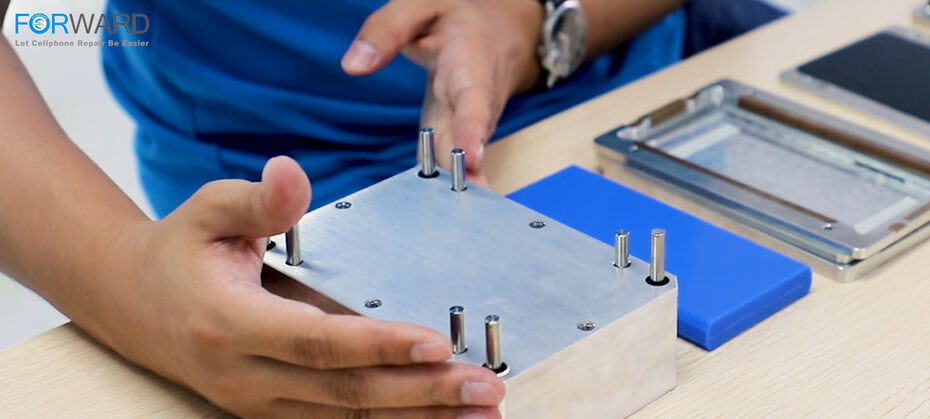

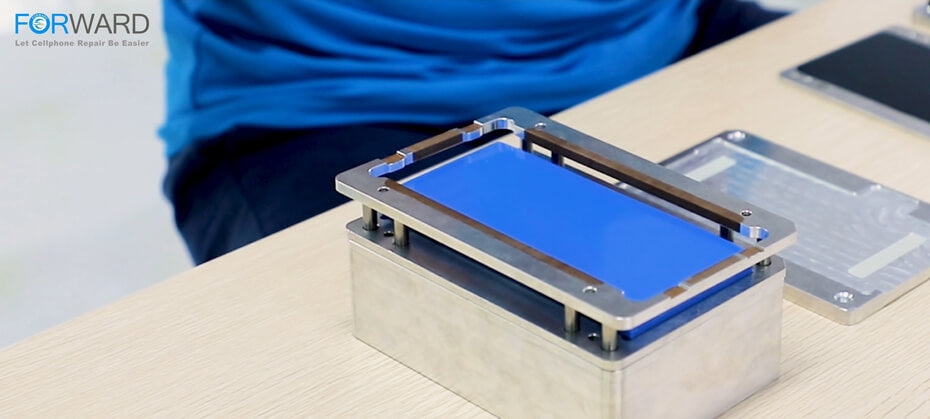

Except that during the lamination, we also need some tools. If you repair edge screens, that tool is our mold. A special-made curved mold. These three molds and one mat. These tools has different models to match different models of curved screens.

On my right side in the picture, there is a base mold and it is a universal base. All models and molds can be used together with this base mold.

The whole effect is seem like this in following picture.

Except two things I mentioned above in the lamination process, we also need to use an important thing, that is our laminating machine.

The model of this laminating machine is RMB-2. It is a two-in-one laminating machine.

What’s inside this two-in-one machine?

Firstly, it has a lamination room. You can do OCA or LCD lamination in this lamination room.

Then bonding a glass to the LCD.

It may appear some bubbles in the middle. We can remove bubbles through this inner closed bubble remover of this machine so that we can finish the entire lamination.

You can see that all can be done in this machine.

Let’s call it a day.

Thanks for reading.