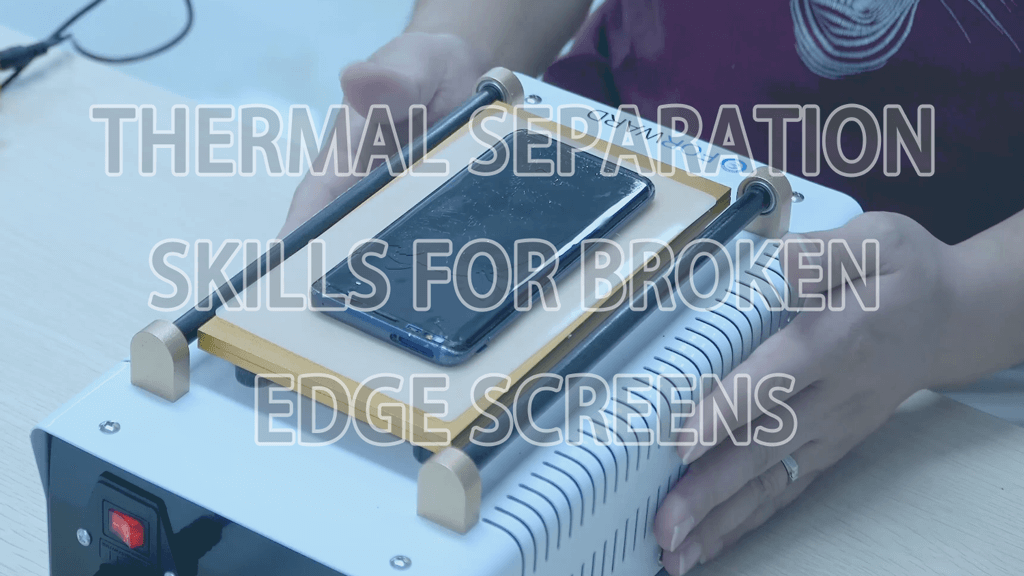

How To Repair Samsung Broken Edge Screens With Thermal Separation?

Difficulty

★☆☆ Low

Step

No

Required Time

No

Excerpt

Whatever you are a novice or a veteran, if you want to increase the success rate of Samsung edge cellphone screen’s refurbishment, do not hesitate to come and see this real stuff. May you can get some useful separation skills from here.

Accessories

Whatever you are a novice or a veteran, if you want to increase the success rate of edge cellphone screen’s refurbishment, do not hesitate to come and see this real stuff.

You know, we usually use two ways to separate edge screens. One is thermal separation, and another is cold separation.

For this time, let’s talk about how to take apart edge screens through thermal separation. As many people like to use Samsung mobile phones and it took the world by storm of its curved screens touch feelings, today we will use Samsung phones an example to discuss thermal separation.

There are two thermal separation methods to separate edge screens.

Method A: Remove mid-frame at first, and then separate the glass

Mid-frame Removing

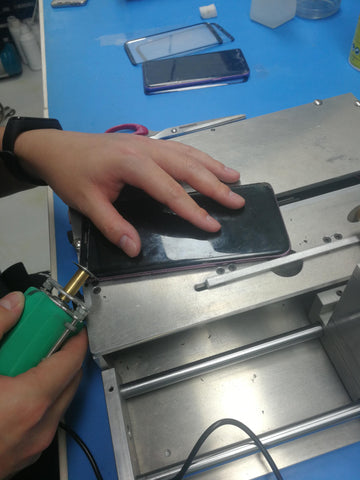

Put a screen on the heating platform of Manual Vacuum Separator. And set the heating temperature to 90℃. Heat it in around 30s.

Cut an OCA film into strips and drop glue remover liquid X11 into the gap of battery tank.

And then scrap the cold glue slowly through the battery tank with a cut strip.

Warm tips: The cut strip should be kept out of the positions of flex cable.

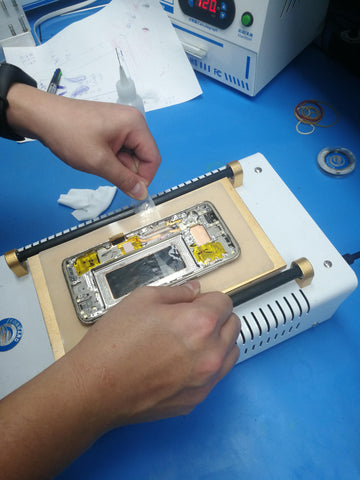

Glass Separating

While separating the glass, the first thing to do is drop on both sides of the glass a glue remover liquid with lubrication and without damaging the LCD (like X11).

Then make a little gap at one corner where can entry separation steel wire with a small card. This is to avoid cutting the wrong layer.

Warm tips:

1. The separation steel wire shall be 0.4mm or less.

2. When separating, the angle formed by the steel wire and the long side of the glass should not be bigger than 30 degrees. This will avoid damaging polarized light.

Tools needed for method A:

Manual Vacuum Separator, separation steel wire 0.4mm or less, OCA film (small card), glue remover liquid X11, a cut pliers

Method B: Separate the glass at first, and then remove mid-frame

Cutting

If you want to separate the glass in advance, you should use a Cutting Machine. Cut off the part of the screen on the top. Use a small manual cutter to cut two small gaps at the top corner of the screen.

Warm tips: When cutting a small gap, do not cut it directly. Only shred the glass gently.

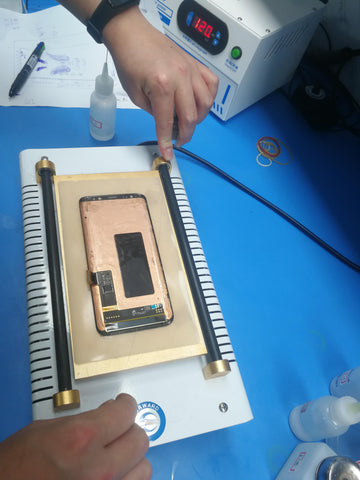

Then put the screen on the heating platform of edge separator. The heating temperature is set to 110℃.

After that, drop glue remover liquid X11 and remove the smash glass with a blade.

Glass Separating

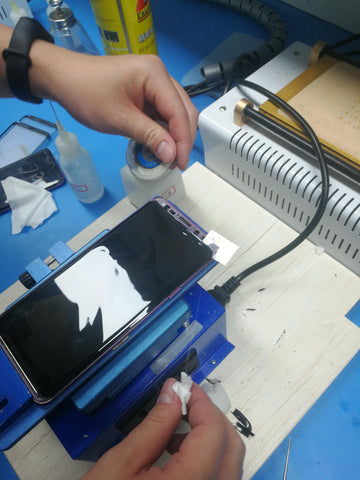

Before the separation, use a blade to drop a little glue remover liquid X11 on both sides of the screen and make a few strokes.

Warm tips: The blade cannot be extended too far to avoid scratching the LCD.

When separating, the angle formed by the steel wire and the long side of the glass should not be bigger than 30 degrees, and separate two sides alternately.

The middle part can be separated in parallel, but both sides of the glass must be separated firstly.

Warm tips: When the separation steel wire can’t enter in the place where the glass is broken, first relax the separation steel wire, then press down the steel wire with a blade, you will find out the steel wire can enter easily while you pull it.

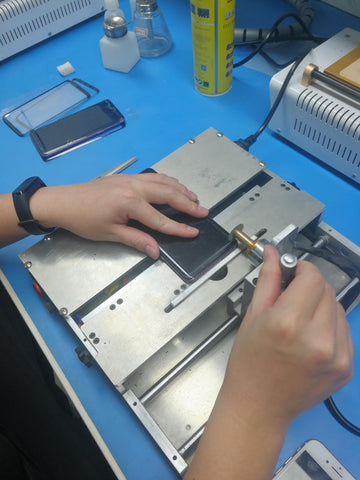

Mid-frame Removing

Scrap a gap with a small card on the top corner of the LCD. Please do not take the small card away.

The separation steel wire goes in from under the small card. Separate the mid-frame from the LCD with a separation steel wire. Separate completely where is without flex cables.

When encountering the position of a flex cable, using the card to dip a little glue remover liquid X11 and scrap the cold glue slowly.

Tools needed for method B:

Small manual cutter, Edge thermal separator, separation steel wire, blade, OCA film (small card), Glue remover liquid X11, scissors

That’s some methods and skills for separating edge screens through thermal separation. No matter which method you use, you can nail it as long as you are full of patient and confident.